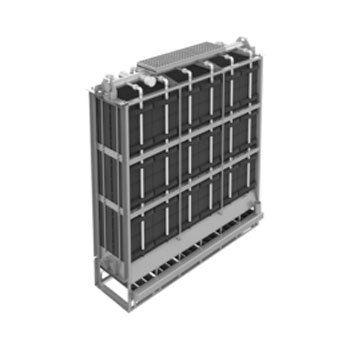

MBR Filter Modules & Systems

“LIKU-TECH” MBR Filter modules are made from high-quality plastic material (Polypropylene) and the components are made of high-grade stainless steel to ensures the highest performance and self-durability. The filter modules sizes are very flexible and can be configured with any modular design.

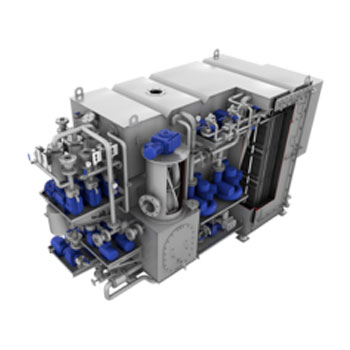

“LIKU-TECH” MBR systems are integrated & compact sewage treatment plant has offers complete on-board systems for maritime application. Vacuum Toilet System, Galley water Treatment, Waste Handling & incineration, Tank Equipment, Mechanical Pre-Treatment, Biological Treatment, Membrane filtration, sludge handling etc.,

Fine Screens

“LIKU-TECH” Fine Screens are used to offer safe and low maintenance operation of MBR modules & systems. This fine screen eliminates hair, fibrous matters, etc., which can form undesirable tangles in membrane biology.

- Simple & compact design.

- High hydraulic flow screening through the finest perforation.

- Combination of screening, sand separation and washing of organic particles.

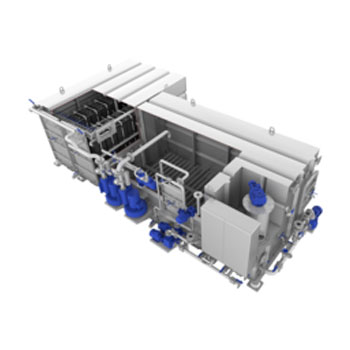

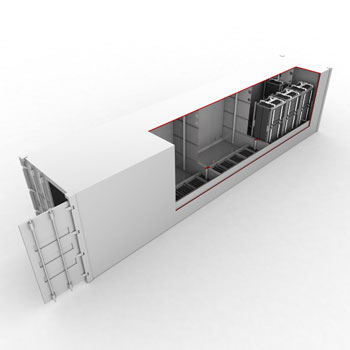

Mbr Packaged / Containerized Treatment Plant

“LIKU-TECH” MBR Packaged & Containerized treatment plant process is combination of membrane filtration & biological treatment. This innovative technology offers several advantages over the Conventional Activated Sludge Process. Among these advantages are higher biomass concentration, eliminating the needs of secondary clarifiers and improved effluent quality.

This process transforms sewage to clear and high-quality water. The small footprint of the treatment technology enables the systems to be integrated in natural, picturesque surroundings and to treat wastewater for irrigation use.

The core technology inside the MBR which consists of polypropylene plates with a polymeric membrane on each side. The membrane is welded on rigid frame. The module reduces virus and bacteria by 99.9999 %. Filter plates are continuously aerated through bubble diffusers to keep them clean. The membranes don’t need regular chemical cleaning except one or two maintenance clearings per year.

We developed compact package systems for MBR plants so that up to 1000 m³/day can be filtered in one 40-foot ISO container. The inside tanks are made of stainless-steel sheets.

Aqua Cube / Cube Mini

“LIKU-TECH” AQUA CUBE is a cost effective, compact, and mobile water treatment plant based on a modular membrane filtration system that enables available water resources to be used purposes such as service water or drinkable water.

The AQUA CUBE is a plug and play device. It is easy to install and operate, has a very low energy consumption, and it is ready to use. Depending on the capacity and type of the plant, installation and operation is even possible without any need of electrical energy or other consumables.

The AQUA CUBE from LIKU-TECH can remove up to 99.99999% of bacteria and other pathogens out of polluted water by means of ultrafiltration filters and make it drinkable.

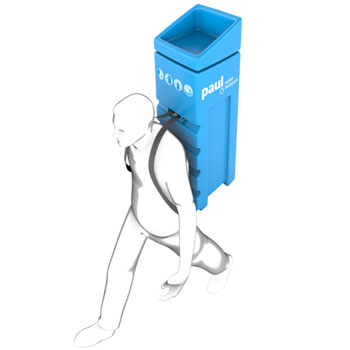

Paul Waterbackpack

“LIKU-TECH” PAUL WATERBACKPACK is a water filter for the quick supply of potable water either in disaster areas or in rural areas. The device filters pathogens out of the water, makes it drinkable and offers effective protection against cholera, typhus, and other infectious diseases. PAUL WATERBACKPACK can be transported to remote areas by just one person as a backpack because it only weighs 20 kg.

The operation of the filter is simple. Dirty water is filled in at the top, after a few minutes the water can be collected at the outlet. The device is highly durable, longer lifetime and it works without energy consumption, chemicals, or additives. It is extremely robust and has no moving parts. As a manual there are simple pictograms, also suitable for public utility.